|

Development of the Double Loon |

||

|

|

||

|

The Double Loon was developed in Canada out of necessity for catching very spooky Rainbow Trout. Their average size at 3 to 5 pounds made any fish caught perfect for the table. The problem was catching one…..just one! Their home, was a deep mountain lake of extreme beauty, where the fish were very much in tune with their surroundings or anything that disturbed it. It was in this setting that I realized, if the fish wouldn't rise to my offering, then I would have to rise to the challenge.

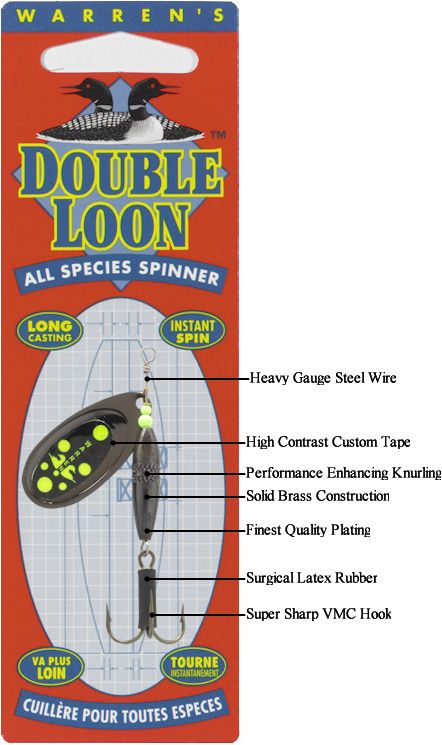

We trolled using electric motors, or silently drifted shorelines while casting spinners and spoons into the structure that lined the lakes shore. We lost tons of tackle, were eaten alive by tiny black flies and were mostly unsuccessful. We tried longer leads when trolling. We used longer rods and cast the shore line with lighter and lighter line, and went to the local tackle shop over and over again for different tackle but had little success. I had to get creative. Most of our success, however limited, came on in-line spinners, so I thought I would use what was available to me in the tackle shops as a starting point. What could I do to make a better spinner? I had to identify the problems common to all spinners and not repeat the errors that the large established companies were making. A good place to start was to read the packaging. Were there any features common to most spinners? I noticed that many of the brand names had one thing in common and that was weight. A #1 would always be 1/8oz. or a #3 would always be 1/4oz. etc. Spinners were first used in France for Brown Trout where shallow streams are the norm and casting for distance was not important. Today, an angler might fish from a dock, walk a river, troll a lake, or cast while drifting a shoreline. Versatility was not your standard in-line spinner's strong point. Spinners had not changed with the times. They just weren't heavy enough to get the job done. Small meant light, and large meant heavy. That was the rule. Small and heavy? It didn't exist. I couldn't find a small spinner that was heavy enough to cast the distance needed to keep my presence hidden from my targeted fish. If I used a larger, heavier spinner I could get the distance I needed, but it was either too big and the fish weren't interested or the big splash would spook them. So I made my own. At first I used readily available component parts and placed coloured tape on the underside of the blades where the fish could see them… in their face. Using store bought component bodies as a start, I then designed my own spinner bodies, making them heavier than the industry standard for their size. I used heavier blades as well and matched hackle or tubing to the tape colour. I experimented and discovered that the proper flash from spinning blades and knurled body surfaces made a huge difference. Knurling was not just a cosmetic feature. It served many purposes from eliminating spinner wobble to adding dozens of reflective surfaces that emit a strobe like flash. The kinks were ironed out at the University of Toronto in the Hydrostatic Lab where, with the help of a Ph.D. in fluid dynamics, I learned about vortices and how they effect the number of RPM that a blade will spin. Getting the blade to spin instantly as well as slowly was a priority. A slow spin emits a heavier thump and creates an instinctive response. It annoys fish. They hit it and when they do the strike is often very violent. They don't need to be feeding to strike. Top quality plating was important too. Matte silver, although dull looking in daylight reflects more light than polished silver or nickel under water and is perfect for stained, dark and deep water or for cold water Trout and Salmon. I then coated the silver with urethane to inhibit tarnishing. Northern Pike find this silver flash irresistible under most conditions. Plating in 24kt gold produces a flawless finish. Gold, unlike brass will not tarnish. There is even a place for nickel. When fishing warm water, the duller flash from nickel will not spook the fish. From mid range temperatures and up ( 45 deg. F.) I use the nickel over the silver. I found top quality hooks that were much sharper than the standard used in the industry, and because of this, once a fish was hooked he stayed hooked. I lost fewer fish. I tried heavier gauge stainless steel than the industry standard for the wire shafts so that if I hung one up on a submerged log and was lucky enough to get it back, it wouldn't be bent out of shape. It could then be used again with success. The Double Loon will take a beating! To re-cap; the Double Loon was designed out of necessity, to catch Trout. Since those early days it has proven itself over and over again on just about anything that swims. Bonefish, Redfish, Permit, Sea Trout, Snook and Tarpon in The Gulf of Mexico, Baramundi in Australia, Tigerfish in Zimbabwe on The Zambezi River and in the far North, Grayling and Arctic Char have fallen to the Double Loon. There have been many world records set using the Double Loon, among them a 50 inch Musky caught and released alive using 6 lb. test while fishing for Walleye! This record is remarkable inasmuch as it was caught on video during the taping of a fishing show. The record stood for several years. The list goes on, as will further development of new products. |

||

|

The lake, far

off the beaten path, had very few dwellings, but it did have its rules.

These rules were designed by the local inhabitants to discourage

development and to protect their pristine surroundings. No trees were

allowed to be cut or moved except those that blocked access to the lake.

The shoreline was left in its natural state. No live bait was allowed. No

gas motors were allowed. There was even a rule about the use of power

tools or hammering on Sundays, and coupled with size and quantity limits,

catching and keeping anything at all was difficult. We could see fish in

the crystal clear water as they swam around our offerings.

The lake, far

off the beaten path, had very few dwellings, but it did have its rules.

These rules were designed by the local inhabitants to discourage

development and to protect their pristine surroundings. No trees were

allowed to be cut or moved except those that blocked access to the lake.

The shoreline was left in its natural state. No live bait was allowed. No

gas motors were allowed. There was even a rule about the use of power

tools or hammering on Sundays, and coupled with size and quantity limits,

catching and keeping anything at all was difficult. We could see fish in

the crystal clear water as they swam around our offerings.